PP/HDPE Woven Bag Making Machine / Printing Machine and Equipment

FOR DAH offers a wide range of HDPE and PP woven bag making equipment, including Automatic Cutting Sewing Machines, Automatic Bag Cutting Machines, Loom Machines, Flexographic Printing Machines, Inspection Machines, and Slitting Machines. Our machines are designed for maximum precision, durability, and efficiency, making them suitable for industries such as agriculture, packaging, and construction. Whether you're producing cement bags, grain bags, or fertilizer bags, FOR DAH's innovative solutions ensure consistent high-quality output and reduced labor costs. Upgrade your production line today with our advanced technology that meets global standards.

-

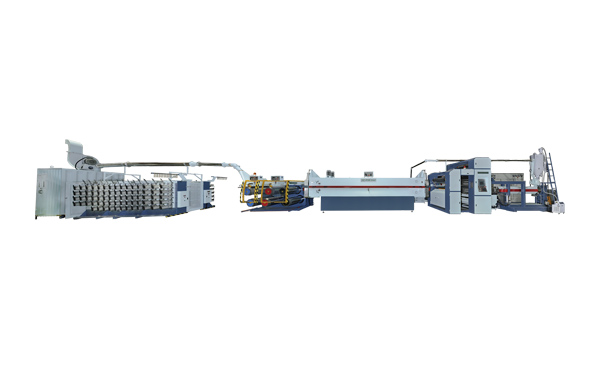

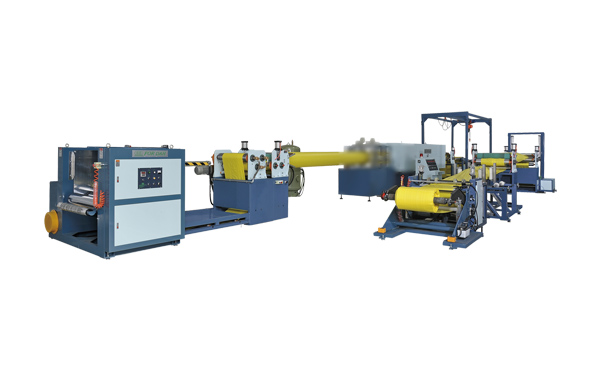

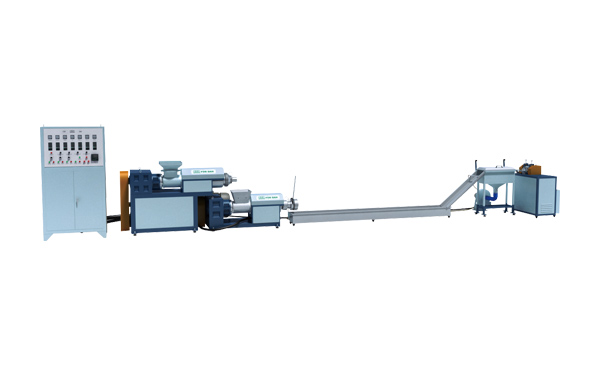

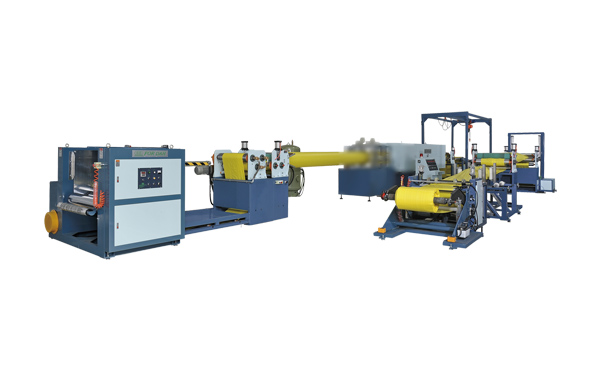

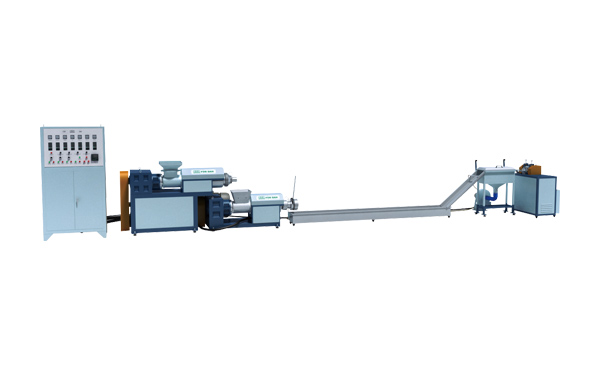

FTH-350 & FTH-500 & FTH-650High Speed & High Capacity Flat Yarn Making Machine

The FTH-350 & FTH-500 & FTH-650 Tape Stretching Line are the ideal machine to produce high quality and precision cross winding packages of PP/HDPE flat tapes. Our High Speed Flat Yarn Making Machine is engineered for maximum efficiency in producing high-quality PP/HDPE flat yarn. With advanced technology and robust construction, this machine offers superior performance in both speed and capacity. Key features include: - High-speed production capabilities - Advanced control system for precise operation - Durable components for long-lasting use - Energy-efficient design What Is a Flat Yarn Making Machine? A flat yarn making machine (often referred to as a “tape stretching line”) is specifically designed to produce high-quality PP/HDPE flat yarn or tapes. By combining accurate extrusion, stretching, controlled heating, and precise winding processes, it delivers consistent, durable tapes used in woven bags, sacks, and other applications requiring strong packaging materials. Frequently Asked Questions About the Flat Yarn Making Machine 1. Which materials are supported? Our line supports PP, HDPE, or blends containing UV stabilizers, colorants, or other additives needed for your application. 2. How can I maintain consistent tape denier? The integrated melting pump and advanced tension control help ensure minimal denier variation across the tape width. 3. What maintenance does the machine require? Regular cleaning of the extrusion die, checking PID controllers, and lubrication of key mechanical parts. Our design reduces friction points to simplify upkeep. Contact us to learn how our High Speed & High Capacity Flat Yarn Making Machine can transform your operations.

-

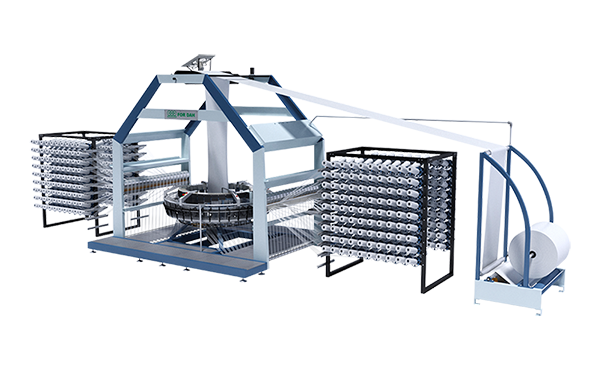

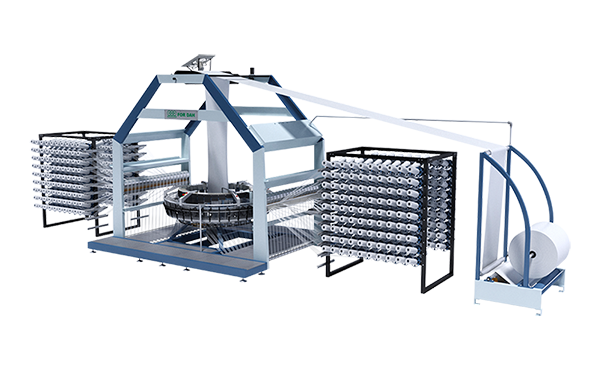

FD-6B/850(S)6 Shuttles Circular Loom Machine

Our 6 Shuttles Circular Loom Machine FD-6B/850 (S) are applied for weaving into tubular fabric from flat yarn spindles. It is suitable to produce variety of fabric sizs for packaging application like fertilizer, animal feed, seed, chemical, cement etc. Designed to weave fabric from 350 to 850 mm tubular fabric, the6 Shuttles Circular Loom Machine FD-6B/850(S) is an advanced design with take-up servo control and human machine interface.

-

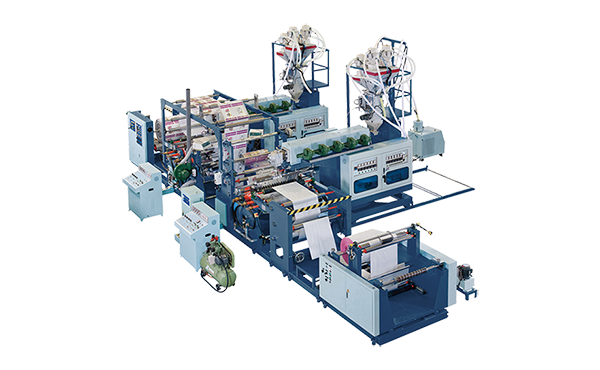

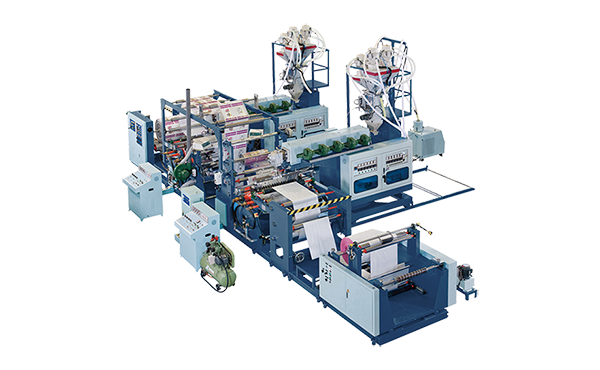

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)Single Side by Turn Bar and Outside Lamination Machine

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)Double Side and Outside LDPE/PP Lamination Machine

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

-

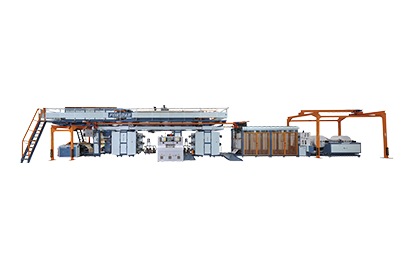

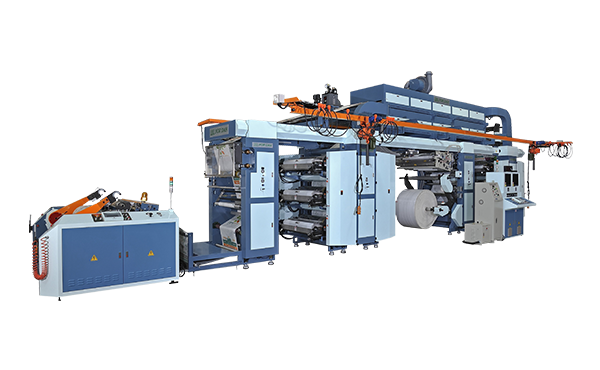

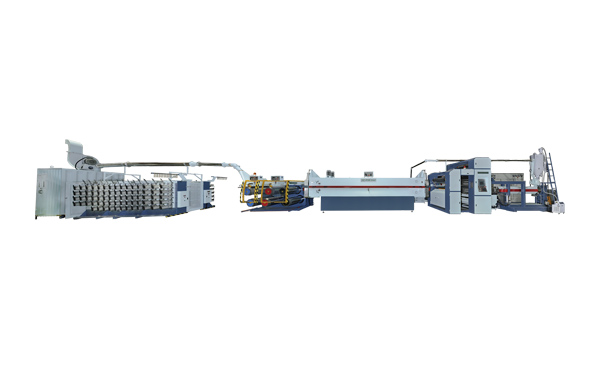

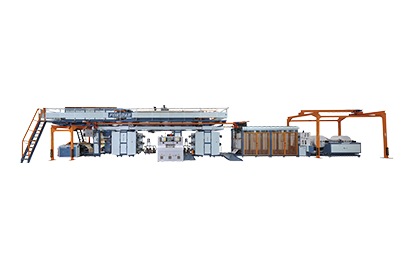

900W series (250M)Flexographic High Speed Roll to Roll 8~12 Color Printing Machine with 2 Printing Stack and 4 Drying Oven (Direct Printing)

Max. machine speed: 250M/Min. Standard including: Additional 2 ovens, CPC, In –feed servo control, Corona treatment, Non-stop Un-winder, Auto. Re-winder & servo control out-feed Our flexographic roll to roll 8~12 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value. Newly developed printing machine offers max. line speed 250M/Min.

-

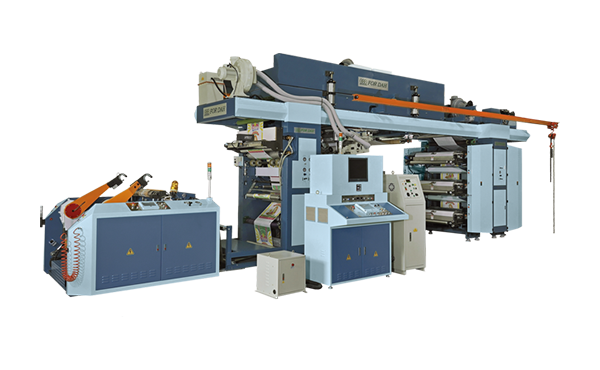

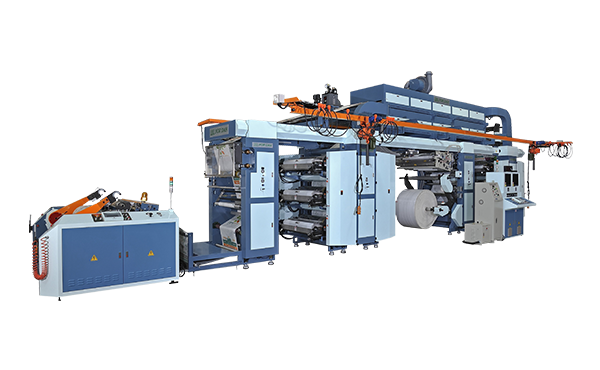

900W series (180M)High Speed Flexographic Printing Machine | Roll to Roll 6~12 Color Direct Printing Machine with 2 Printing Stack

Max. machine speed: 180M/Min. Standard features include: Non-stop Un-winder, Auto Re-winder, out-feed by servo control, and Corona treatment. Our high-speed flexographic printing machine, designed for roll to roll 6~12 color direct printing, is ideal for solvent-based ink applications on PP woven bags, with or without lamination. It supports CMYK color combinations to achieve realistic printing quality, enhancing the packaging value.

-

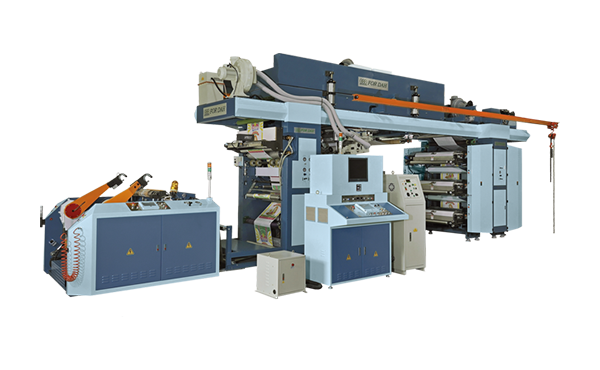

900W Series (120M)Flexographic Roll to Roll 4~6 Color Printing Machine with Single Printing Stack (Direct Printing)

Max. machine speed: 120M/Min. Standard including: Corona treatment The flexographic roll to roll 4~6 color printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination. Available for CMYK color combination to obtain realistic printing quality to enhance packing value.

-

300 SeriesFlexographic Double Side Servo Control 4~9 Color Roll to Roll Printing Machine (Indirect Printing)

Our double side servo control flexographic 4~9 color roll to roll printing machine is applied for solvent-based ink and indirect printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

R400 SeriesFlexographic Single Side 4~6 Color Roll to Roll Printing Machine (Direct Printing)

Our single-side 4~6 color roll-to-roll flexographic printing machine is specifically engineered for roll-to-roll printing applications with solvent-based ink. It excels in direct printing without the need to change the plate cylinder, which significantly enhances efficiency and reduces downtime. This machine is particularly well-suited for printing on PP woven bags, whether laminated or unlaminated. With its innovative design and precise CMYK color combination, it ensures exceptional print quality, outperforming traditional piece-to-piece printing methods. Equipped with advanced technology for optimized performance and reliability, our roll-to-roll printing machine boasts user-friendly controls for seamless operation, even for operators with minimal experience. Whether handling large volumes or small batches, it offers unparalleled versatility and durability for any printing operation.

-

FD-TG 60PP Woven Cloth Tubing Machine

The PP woven cloth tubing machine is designed to tube coated or laminated flat fabric into a flat or side gusset tube in roll.

-

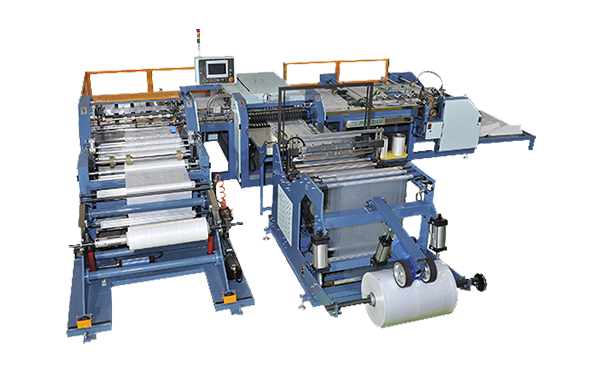

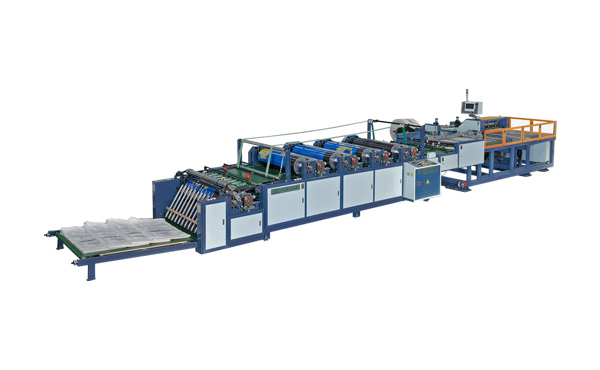

FD-IST-650 + FD-ILM-850Line of PP Tubular Fabric Film Inserting And Inside Lamination Machine

Our PP tubular fabric film inserting and inside lamination machine, combined with the PP Woven Bag Inner Liner Insert Machine, is designed for producing PP woven inside laminating bags by bonding the two-layer liner with outer woven cloth, utilizing a high-quality PP lamination machine. This setup is ideal for waterproof packaging of chemical materials, fertilizers, feed, flour, sugar, fish meal, powder, and more. It offers easy operation and labor-saving automation, increasing production efficiency and minimizing human error.

-

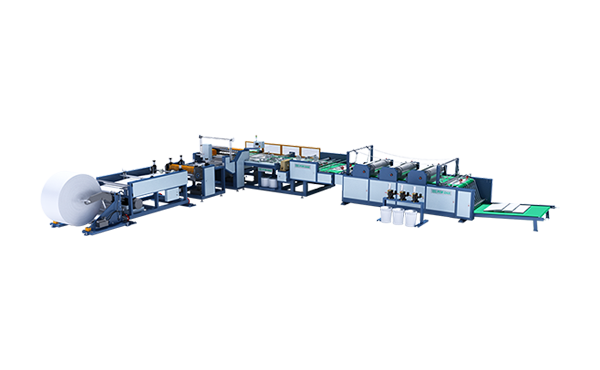

RS-3CHigh Speed Auto. Cutting & Sewing Machine

The automatic cutting and sewing machine is the final stage to perform cutting, bottom folding, sewing and stacking to finish PP woven bag in one continuous operation. The machine is equipped 4 sets bag clipper that ensures smooth bag feeding and suitable for low denier PP woven bag. Special purpose for producing BOPP laminated bag, gusseted bag, easy open bag, perforated bag, punched bag, handle bag, double stitching bag, leno bag are also available upon the clients’ request.

-

FD-INF-850Auto. Liner machine for Cutting-Inserting -Sewing (With Bag Clipper)

PP woven bag with PE liner is an ideal packing for the product that requires the highest protection especially the fine grade and pulverous material such powder, chemical, salt, sugar, flour, and other similar product. The machine is developed to replace the traditional working process to insert liner into the woven by manual. With automatic online working process benefits the saving of labor and higher production efficiency.

-

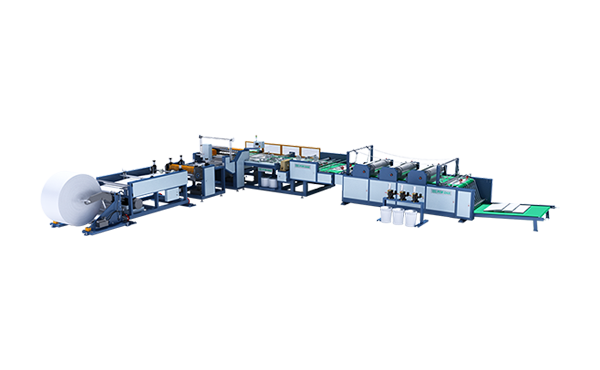

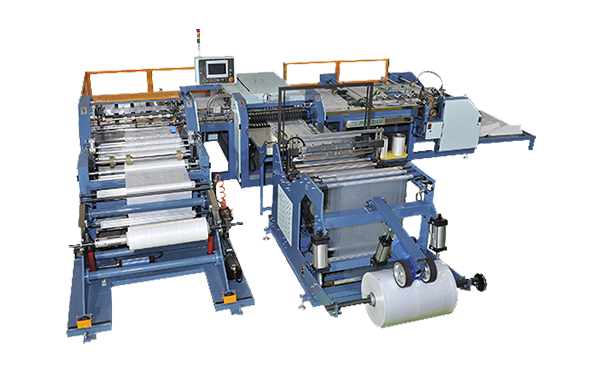

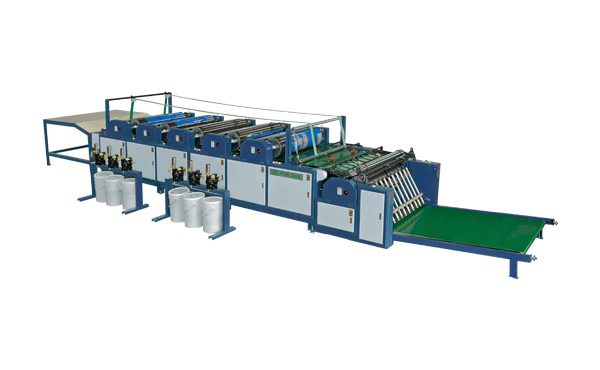

500-3C SeriesAuto. Cutting, Sewing and Single Side 2~6 Printing Machine

Our automatic cutting, sewing and single side 2~6 printing machine is the combination of auto. cutting & sewing machine and single side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

-

ED600-3C SeriesAuto. Cutting, Sewing and Double Side 2~6 Printing Machine

It is the combination of auto. cutting & sewing machine and double side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

-

GS-80Gusseting & Rotating Machine

The gusseting and rotating machine is designed for making side gusseting and rotating in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

G-80Gusseting Machine

The gusseting machine is designed for making side gusseting in a roll to roll operation. Available for PP woven bag, laminated woven, and BOPP laminated bag.

-

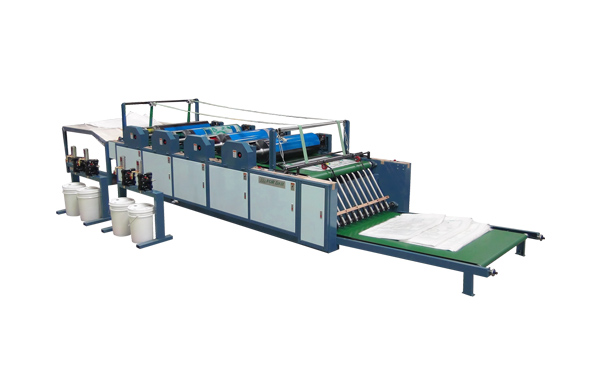

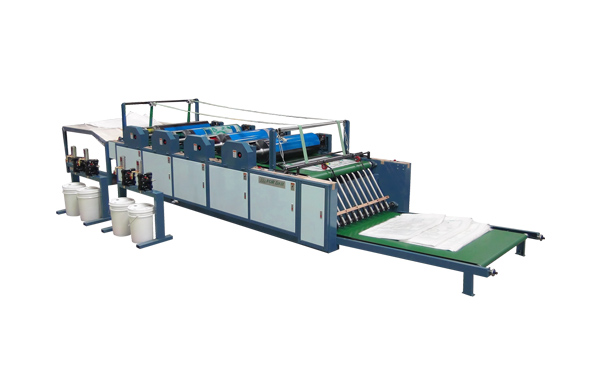

E400 SeriesSingle Side 2~6 Color Piece to Piece Printing Machine -Horizontal Feeding (Direct Printing)

The bag will be fed by horizontal direction. Our single side 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

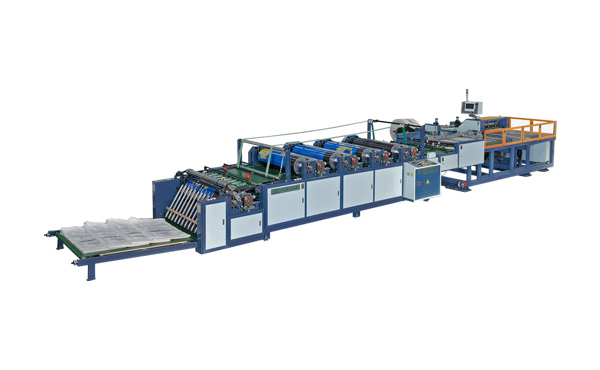

ED400 SeriesDouble Side 3~6 Color Piece to Piece Printing Machine (Direct Printing)

It is available for double side printing. The double side 3~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for double side ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

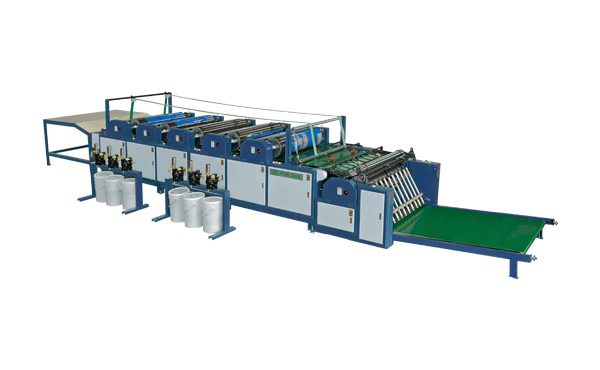

H400 SeriesSingle 2~6 Color Piece to Piece Printing Machine -Vertical Feeding (Direct Printing)

The bag will be fed by vertical direction. The single 2~6 color piece to piece printing machine is applied for solvent-based ink and direct printing method for PP woven bag with/without lamination, it is suitable for ordinary printing with simple pattern i.e logo, words, image, which is required for stuff presentation and company identification.

-

FD-30Hydraulic Baling Press

Our hydraulic baling press is applied for compressing woven bag with the working of hydraulic cylinder to be packed in bundle to save the space and easy for transportation.

-

FD-PR 140/120Waste Recycling Machine

Our waste recycling machine is applied for in-house recycling waste like HDPE/PP woven tapes, woven fabric, printed woven bag, film flakes etc. The pellets produced by the recycling machine can be used again directly in extrusion process as part of mixture to reduce the cost of raw material.