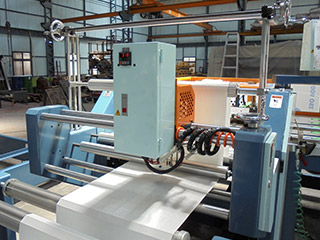

Auto. Cutting, Sewing and Double Side 2~6 Printing Machine

ED600-3C Series

It is the combination of auto. cutting & sewing machine and double side printing machine to be online operation to perform a ready bag. With auto. online working process ensures the saving of labor with productive capacity.

Features

- Cutting unit and printing unit works simultaneously that minimizes the miss of printing job.

- Convenient operation and trouble-free to take care the machine easily.

- Selection of either auto. cutting & sewing unit or printing unit is available upon request.

- With working table to manually feed bag for printing without processing from auto. cutting & sewing unit.

- The unwinder is with pneumatic pedal device to lift the fabric roll easily without any mechanical tools.

- The cloth feeding is driven by dancing roller to maintain uniform tension of the fabric.

- Dual servo control for cloth feeding and bag clamping minimizes the cutting length variation.

- The clipper arm is mounted with silicone screw to avoid pricking the surface of bag.

- EPC device to control the edge position for varying web width.

- Union Special sewing head is available on customers’ request.

- With colorful operator-friendly human machine interface (HMI) offers English, Spain, Russia, Arabic, Chinese, French to access the machine operation easily.

- In case of no bag is fed to the ink rollers the printing roller will separate automatically to prevent ink staining the conveyor to keep clean on the bag.

- Special design of anilox roller and ink roller to prevent splashing of ink.

- Equipped with cubic differential transmission for each color to make printing registration (up/down, right/left) without stopping machine.

- With auto. ink circulation device to maintain uniform ink viscosity giving good printing quality.

Inline Edge Rotating & Gusseting Device

Punching Device

Micro-Perforation Device

Double Stitching Device

Human-Machine Interface control

Back Side Printing