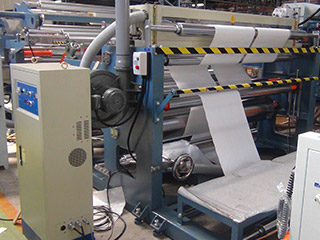

Double Side and Outside LDPE/PP Lamination Machine

FD-LA75(D) & FD-LA90(D) & FD-LA100(D)

The double side and outside LDPE/PP lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

Features

- Double Side and Outside LDPE/PP lamination machine: High-Efficiency Control and Precision.

- Our Double Side and Outside LDPE/PP lamination machine adopts SCR control for power saving and features a precise PID temperature controller, ensuring optimal operational efficiency for plastic film lamination.

- The entire operation of our LDPE/PP lamination machine is synchronously controlled by a robust PLC program. It is easy to operate through an intuitive HMI interface for setting recipes, controlling temperature, counting length, and reviewing alarm records, enhancing the user experience in the lamination process.

- The brake system for the unwinder in this LDPE/PP lamination machine is a clip-type pneumatic brake, designed to keep the machine working long-lasting and stable, particularly during high-speed lamination operations.

- Equipped with a Pre-Heating Roller and a heating pipe, our LDPE/PP lamination machine effectively treats materials to achieve excellent sticking effects, crucial for high-quality lamination.

- The Mirror Finished Chill Roller gives a shiny appearance on the laminated bag, providing a smooth basis prior to printing, which is essential for printing industries using LDPE/PP lamination machine.

- Our Printing Mark Tracking System enhances the functionality of the pp lamination machine by accurately tracking the printed BOPP on both sides. This is done through a precise tension controller, a color mark sensor, and sophisticated software, ensuring flawless alignment and lamination quality.

BOPP Un-winder

Lamination UNIT

Corona Treater

Sensor for Edge Trimming

Surface Winder Device