Single Side by Turn Bar and Outside Lamination Machine

FD-LA75(S) & FD-LA90(S) & FD-LA100(S)

The single side by turn bar and outside lamination machine are used for coating of thin layer of Polyolefin (mainly LDPE/PP) on substrates like woven fabric, BOPP film, paper, jumbo bag (FIBC) etc, which is for moisture-proof, dust-proof, and structurally strong enough.

Features

- Adopts “Turn Bar” to make double side lamination in one time with one extruder.

- Adopting SCR control for power saving and precise PID temperature controller.

- Machine is synchronously controlled by PLC program and easy to operate through HMI for receipt setting, temperature control, length counting, alarm record.

- The brake system for unwinder is clip type pneumatic brake that keeps machine working long-lasting.

- With Pre-Heating Roller and heating pipe to treat the material to get the good sticking effect.

- Mirror Finished Chill Roller (Optional) gives the shiny appearance on the bag to provide the smooth basis prior to printing.

- Printing Mark Tracking System (Optional) of the printed BOPP on both sides by means of precise tension controller, color mark sensor and software.

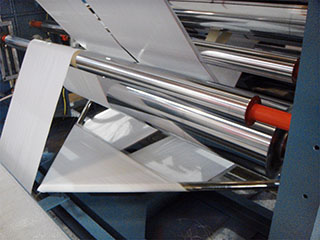

Turn Bar

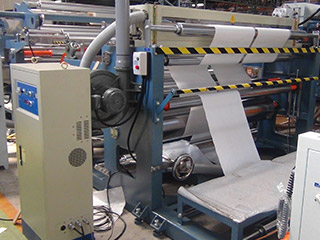

BOPP Un-winder

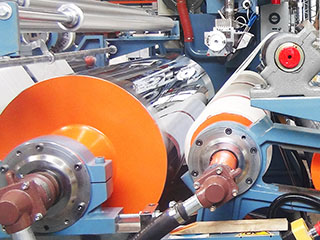

Lamination UNIT

Corona Treater

Sensor for Edge Trimming

Surface Winder Device